THEY DELIVER

THEY DELIVER

SOO MARINE SUPPLY keeps the boats supplied

A spotlight on Soo Marine Supply, as featured in Shipwatcher News Freighters issue 78, Spring 2025.

They Deliver

SOO MARINE SUPPLY KEEPS THE BOATS SUPPLIED

By Brendan Falkowski and Ryan Miller

The authors visited the Soo Marine Supply warehouse and were able to observe a supply run to the Stewart J. Cort in June 2024. Special thanks to Soo Marine Supply General Manager Brent Belanger for making this possible.

Nestled down off Portage Avenue along the St. Marys River in Sault Ste. Marie, MI, Soo Marine Supply (SMS) has been serving Great Lakes freighters for over 124 years. While it may not appear like much from the road, down that driveway lies a vital supply line necessary for provisioning the ships, but more importantly the crews. The ships run from March to January with little time to stop while in port. Soo Marine Supply provides a solution, delivering groceries, supplies, and people to the ships as they pass by Sault Ste. Marie, MI.

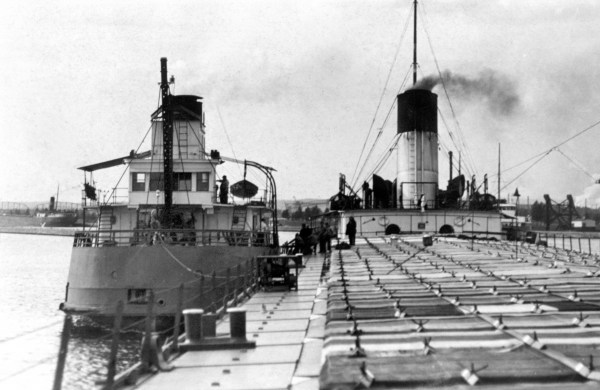

The service was first initiated in 1901, served by the wood-hulled ferry Superior. She operated in the supply boat capacity from 1901 to 1917 when she was replaced by another reconstructed ferry, the Frontier. Frontier served as the Soo supply boat from 1917 until June 1, 1947, when the current supply boat, Ojibway, entered service. The supply service was originally started to stock U.S. Steel’s newly-created Pittsburgh Steamship fleet with ice, food and groceries, parts, and other supplies, but also later served the fleets of Bradley Transportation, Great Lakes Steamship, and Hutchinson & Co. U.S. Steel spun off the supply boat service with their marine division in the late 1980s. The warehouse and supply boat Ojibway were sold to MCM Marine in 2003, who renamed the business Soo Marine Supply and continues to supply the ships today.

Soo Marine primarily serves the American fleets of Interlake Steamship Co., Great Lakes Fleet, and VanEnkevort Tug & Barge, as well as other vessels by request. SMS doesn’t operate on contracts with the shippers, but rather on an on-demand basis, making deliveries and fulfilling services when they are needed.

SMS General Manager Brent Belanger explained to us the different supplies they can and have delivered. He produced from his desk a stapled packet of paper and passed it to us to look through. On the pages were roughly 500 lines of everything you’d expect to find at your local grocery store, apple sauce, pudding, soap, and paper towels. While flipping through the many pages, Belanger continued to explain the various other supplies like gear oil, steel cables, argon tanks, and deployable life rafts that were on the order form. In addition to the listed items there is a final page that’s blank with lines where freighter crews could request specific items that Soo Marine Supplies would then source. In addition, they can perform crew transfers with rental cars arranged and personal storage lockers for their gear.

Orders are put in by the ships about 36 hours prior to passing through the Soo Locks, giving the crew at SMS enough time to pull together everything in preparation for delivery. For some special orders that may not be stocked in the warehouse, SMS crew will make runs out to local stores to attempt to find requested products.

Typically, a big order would be placed at the beginning of the season during fit-out. The crew needs to eat. Supplies need to be stocked. Soo Marine’s tasks during fit out can include requisitioning necessary spare parts for preventative maintenance, extra engineering supplies, replacement safety gear, and stocking the kitchen by ordering nonperishable bulk baking or cooking ingredients. The SMS crew loads supplies into their trucks for destinations ranging from Sturgeon Bay and Superior, WI, to Toledo, OH, and even Erie, PA, to get the ships ready to go. Throughout the shipping season, crews place additional orders to restock perishable and consumable goods. While resupplies can occur at ports, receiving them while underway is most convenient for the crew. As so many boats pass through the Soo Locks, it’s a natural place to have a transfer location.

The facility includes two main warehouses: a stock room and a staging room. Walking through the staging room, shelving units were labeled with bright red tags punched with the names like Hon. James L Oberstar, Mesabi Miner, and other iconic freighters. The traces of heritage were evident even in the warehouse where a hard-to-reach shelving unit still bore a Henry Ford II name tag. On these shelves were custom metal skids that could be moved with a high-low or picked up by crane. Workers assembled orders by picking supplies from the stock room and moving them to the awaiting skids in the staging room. After being shown around the warehouses, it was time to get aboard the supply boat Ojibway.

The Ojibway is a short and stout looking resupply boat that was designed and built in 1946 following World War II. It’s clearly designed for working. In the center of the boat sits a superstructure with a spartan interior that mainly serves to elevate the pilot house and a crane. The crane, on a turntable, is able to rotate off the sides to transfer supplies onto the deck of passing freighters. Aft of the superstructure is an open deck to load cargo. Sectioned into four quadrants, skids are loaded nicely with enough room between them to let crew walk around them. Below deck is the engine room with a rather healthy amount of space – definitely enough room to get a wrench in. While old, the Ojibway is not poorly maintained. She starts with no hesitation and the crane runs smoothly.

As the approaching ship exits the Soo Locks – when supplying while downbound – or rounding Mission Point when upbound, the boat crew heads out to Ojibway for their sprint out to the passing freighter. On June 28, 2024, Ojibway was supplying the downbound Stewart J. Cort. Typically, ships are supplied while transiting downbound, though some are supplied on the upbound. In an interesting situation of policy, a vessel is considered soil of the country it most recently made port, so a vessel that most recently called on a US port is considered “American soil” and one that called on a Canadian port is considered “Canadian soil”. In order to avoid some extra paperwork, vessels are almost always supplied when considered “American soil”.

Once on board now operating as captain, Belanger provided the safety brief: respect the crane and stay clear of the deck crew. He went belowdecks to fire up the single diesel engine, then he climbed the three ladders up to the wheelhouse at the top deck. Three more crew got onboard – two deckhands and a crane operator – before lines were cast off and Ojibway got underway. The supply boat makes way towards the Soo Locks to rendezvous with the Cort. As Ojibway comes to meet the Cort, she turns in a big, swooping turn and pulls up alongside. Over the VHF, Belanger established communication with the bridge of the Cort to synchronize speed and establish a rafting location. A single line is cast down to the bow of the Ojibway to hold her in place; the momentum of the Cort’s forward motion helps keep Ojibway tight alongside.

Nearly as soon as the line is tied off, the crane operator gets right to work. The first skip is already loaded in the bridle and ready to go. Like clockwork, the crane operator makes the whole operation look easy, quickly and smoothly moving the skips full of supplies from the fantail of the Ojibway up to the spar deck on the freighter. The two deckhands help load and unload skips on Ojibway, while the crew of the Cort take care of the operation up on deck. Next went the odd shaped items, a coil of wire rope and bundle of steel tubes were picked and hoisted aboard. After all of the supplies are unloaded from the skips on the Cort, the crew then loads up any trash and recycling to send back to shore. The reverse process ensues, loading everything back onto Ojibway. After the transaction is complete, the line is cast off and Ojibway heads back to home base. A traditional Great Lakes greeting, one long and two short blasts on the horn, were exchanged as the vessels part ways. Meanwhile Stewart J. Cort continues her trip to Burns Harbor, IN, to unload her belly of taconite pellets.

As the Ojibway comes back to the dock, she swoops up from the east and gracefully brushes up against the dock. The lines that were cast only half an hour earlier were retied again. The diesel downstairs is shut down and the crew immediately begins unloading the boat, swiftly slinging skips back up to the dock and unloading the trash and recycling from the Cort. Trash is sent to the dumpster, while the recycling is all sorted and stowed in a customized recycling trailer. When full, the trailer is taken to the recycling center to be emptied. Interlake Steamship Company and other companies have specific agreements with Soo Marine Supply to handle refuse. Soo Marine Supply keeps a cardboard recycling trailer at the dock. Working with Northern Transitions (NTI), Soo Marine Supply is able to responsibly dispose of waste. The crew all return to their respective places, awaiting the call for the next supply run.

We were left with a new appreciation and respect for the Soo Marine Supply group and their employees. This glimpse into Soo Marine Supply shows the critical role that smaller companies contribute to making the Great Lakes shipping ecosystem healthy and efficient. It was clear the Soo Marine Supply crew knew their responsibilities, all the way from perfect docking alongside the Cort and back at the dock to effortless equipment operation and solid communication leading to a safe work space.

Replies to this email are sent to the editor of Shipwatcher News

Discover more from Shipwatcher News

Subscribe to get the latest posts sent to your email.